Exploring the Beauty and Manufacturing Process of Engineered Quartz

Engineered quartz has become a sought-after material for countertops, thanks to its durability, versatility, and stunning aesthetics. In this blog, we will delve into the world of engineered quartz, discussing the various quartz countertop sizes available, the manufacturing process of artificial quartz stone slabs, and how quartz is made.

Quartz Countertop Sizes: Finding the Perfect Fit

One of the advantages of engineered quartz is the availability of different countertop sizes. Whether you have a small kitchen or a spacious bathroom, there is a quartz countertop size to suit your needs. From standard sizes to custom dimensions, quartz countertops can be tailored to fit any space. This flexibility allows homeowners and designers to create functional and visually appealing surfaces that seamlessly integrate into their design vision.

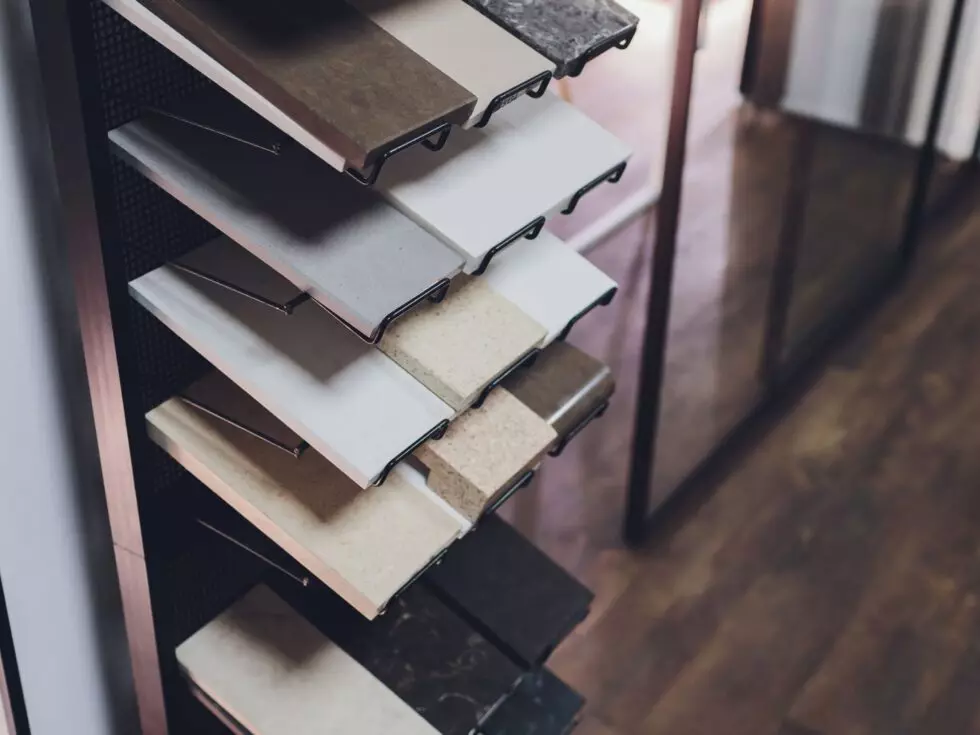

Artificial Quartz Stone Slabs: The Beauty of Engineered Quartz

Engineered quartz is created by combining natural quartz crystals with resin binders and pigments. The result is a stunning and durable material that offers a wide range of colors, patterns, and textures. Artificial quartz stone slabs are manufactured in a controlled environment, ensuring consistency in quality and appearance. These slabs can be customized to mimic the look of natural stone, such as marble or granite, while offering superior durability and resistance to stains and scratches.

The Manufacturing Process of Engineered Quartz:

1. Raw Materials:

The process begins with carefully selected quartz crystals, which are crushed and cleaned to remove impurities.

2. Mixing:

The crushed quartz is mixed with resin binders and pigments to create a homogeneous mixture. The ratio of quartz to resin determines the final characteristics of the engineered quartz.

3. Molding:

The mixture is poured into molds of various sizes and shapes, depending on the desired end product. The molds are vibrated to remove air bubbles and ensure a smooth surface.

4. Pressing and Curing:

The filled molds are subjected to high pressure and heat to compact the mixture and facilitate the curing process. This step ensures the formation of a solid and durable slab.

5. Trimming and Finishing:

Once cured, the slabs are trimmed to the desired size and thickness. The edges are shaped and polished to achieve a refined and seamless appearance.

How Quartz is Made: A Natural Wonder

Quartz, the primary component of engineered quartz, is a naturally occurring mineral found in abundance. It is formed deep within the Earth’s crust through a combination of heat and pressure over millions of years. The extraction of quartz involves mining and careful processing to obtain the purest form of the mineral. This natural wonder is then transformed into the beautiful engineered quartz slabs we see in homes and commercial spaces.

Engineered quartz offers a perfect blend of beauty and functionality, making it an ideal choice for countertops. With a variety of quartz countertop sizes available, you can find the perfect fit for your space. The manufacturing process of artificial quartz stone slabs ensures consistent quality and allows for customization to suit various design preferences. Understanding how quartz is made highlights the natural origins of this remarkable material. Consider engineered quartz for your next project and enjoy the durability, versatility, and stunning aesthetics it brings to your space.